Steam Boiler | Working Principle and Types Of Steam Boiler

What Is Steam Boiler?

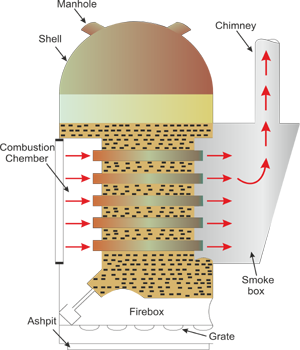

Steam boiler is nothing but a closed vessel combustion chamber which generates steam at a desired pressure by the combustion of fuel to water. Steam is supplied to the steam boiler in differen field like steam engine,steam turbine,thermal power plant,various heating installation process,different cotton mills,sugar factories etc.

Working principle of steam boiler

Working principle of steam boiler is very very simple. Steam boiler is a cylindrical shape closed vessel which has sufficient capacity to contain water and steam.Generally, water or other fluid is stored in steam boiler to generate steam.This water or fluid is heated by flames or hot gasses which are produced by combustion of fuels and consequently steam is generated in the boiler at different pressure according to boiler's size and it's specification.This steam is now passed through a pipe and supplied into different production unit,power plant etc.This is very basic working principle of steam boiler.

Important Component of steam boiler

1. Boiler shell

2. Combustion chamber

3. Grate

4. Furnace

5. Heating surface

6. Mounting

7. Boiler accessories

a) Water level indicator

b) Pressure gauge

c) Safety valve

d) Stop valve

e) Blow off cock

f) Feed check valve

g) Fusing plug

Characteristics of a steam boiler

There are lot of good characteristics required for an ideal steam boiler.But we will describe some important points.

1. It will produce maximum quantity of steam with minimum fuel consumption.

2. It should be light weight and require small space.

3. It can handle any fluctuating load.

4. It should be economical and should require less attention.

5. It should be quick starting.

6. The joint should be few and accessible for inspection.

Types of steam boiler

There are different types of steam boiler used according to their working ability -

1. According to the contents in the tube

According to the contents in the tube,steam boiler is two types.

1. Fire tube or smoke tube boiler

2. Water tube boiler

When hot gases and flames are passed through the tubes or multi-tubes which are surrounded by water, is called fire tube or smoke tube boiler.It is very simple small capacity type boiler and is used various industries for it's simplicity. Example:Cochran boiler,Lancashire boiler,Cornish boiler etc.

In water tube boiler,water is circulated inside the tubes which are surrounded by flames or hot gases. Example:Babcock and Wilcox boiler,La-mont boiler

2. According to the position of the furnace

1. Internally fired boiler

2. Externally fired boiler

When the furnace is located inside the boiler she'll,called internally fired boiler and the furnace is located outside the boiler is called externally fired boiler.Lancashire boiler is an example of internally fired boiler and Babcock and Wilcox boiler is externally fired boiler.

3. According to the axis of shell

1. Vertical boiler

2. Horizontal boiler

In vertical boiler,axis of shell is vertical .Example: Coachran boiler. In horizontal boiler,axis of shell is horizontal.Example : Lancashire boiler.

4. According to no of tables

1. Single tube boilers

2. Multi-tubular boilers

There is only one fire tube present in single tube boiler and two or more tube is present in multi-tubular boilers.Cornism boiler is single tube boiler and Lancashire and locomotive boiler is multi-tubular boiler.

5. According to the circulation of boiler and steam

When water in the boiler is circulated by natural connection currents produced by the application of heat,called natural circulation boilers and water is circulated forcefully by a centrifugal pump called forced circulation boilers.Lancashire,locomotive,and Babcock Wilcox boilers are natural boiler and benson ,voles boiler are forced circulation boilers.

6. According to the use

1. Stationary boilers

2. Mobile boiler

Stationary boiler is fixed boiler and does not move hear and there.It is used in various power plants. Mobile boiler is that kind of boiler which move one place to another.locomotive and marine boiler is mobile boilers.

Efficiency of steam boiler

Efficiency of steam boiler is defined as the ratio of heat utilised by feed water for conservation into steam to the heat released by the complete combustion of the fuel in the same time.This is known as the thermal efficiency of the steam boiler.

In the above equation,

ma = Actual evaporation in kg per kg of fuel burnt.

H = Enthalpy of 1 kg of steam in kJ.

h1 = Enthalpy of 1 kg of feed water entering the boiler in kJ.

C = Calorific value of fuel in kJ/kg.

If the boiler is equipped with an economiser and superheater ,then the efficiency is known as the overall efficiency of steam boiler.

Comparison between water tube and fire tube boiler

| Water Tube Boiler | Fire Tube Boiler |

|---|---|

| 1) It can generate steam at high pressure (upto 162 bars ads) | 1) It can generate steam at high pressure (upto 24 bars ads) |

| 2) The rate of steam production is upto 45☓104 kg/hr. | 2)The rate of steam production is upto 9000 kg/hr. |

| 3) It can produce steam upto 5600C. | 3) It can produce steam upto 3400C. |

| 4) The water circulation is good. | 4) The water circulation is poor. |

| 5) It is used large power plants and ships. | 5) It is not used in large power plants. |

| 6) The operating cost is more. | 6) The operating cost is less. |

| 7) It's transportation and erection is easy. | 7) It's transportation and erection is difficult. |

| 7) The area required for this type of boiler is less (5 m2 per 1000 kg/hr). | 7) The area required for this type of boiler is more (8 m2 per 1000 kg/hr). |

| 8) Its overall efficiency with economiser is about 90 per cent. | 8) Its overall efficiency with economiser is about 75 per cent. |

| 9) It is preferred for widely fluctuating loads. | 9) It is used for suddend incrising loads but for short time. |